E2E Service

Planning and Completions

Guided Installation for Custom Configurations

Upwing application engineers will plan your completion and wellsite configuration, provide deployment and startup procedures and have the ability to intervene using the latest API standards when necessary.

Our team will also lead the planning of the installation, operation and retrieval of the Subsurface Compressor, which is capable of utilizing all industry standard equipment for the downhole completion.

Planning

What's Included

The planning of your completion is based on well production data, including but not limited to:

- Bottomhole Pressure Surveys

- Christmas Tree Profile

- Current Wellbore Completion

- Deviation Report

- Daily Production Data

- Wellhead Temperatures and Pressures

Trusted Guidance

Upwing will help with the procurement and planning of all assets for the installation. Any necessary downhole completion equipment purchases, rig and labor scheduling and wellhead changes will be arranged with Upwing’s guidance and your approval.

Upwing’s Control Center will be sized and selected based on your site’s required power delivery and available utilities. The surface equipment, stored in the temperature regulated control center, will be installed with minimal footprint to ensure operators and personnel can complete their standard tasks without interruption. During installation, Upwing field engineers will be on site to lead the installation from start to finish.

Completions

What's Included

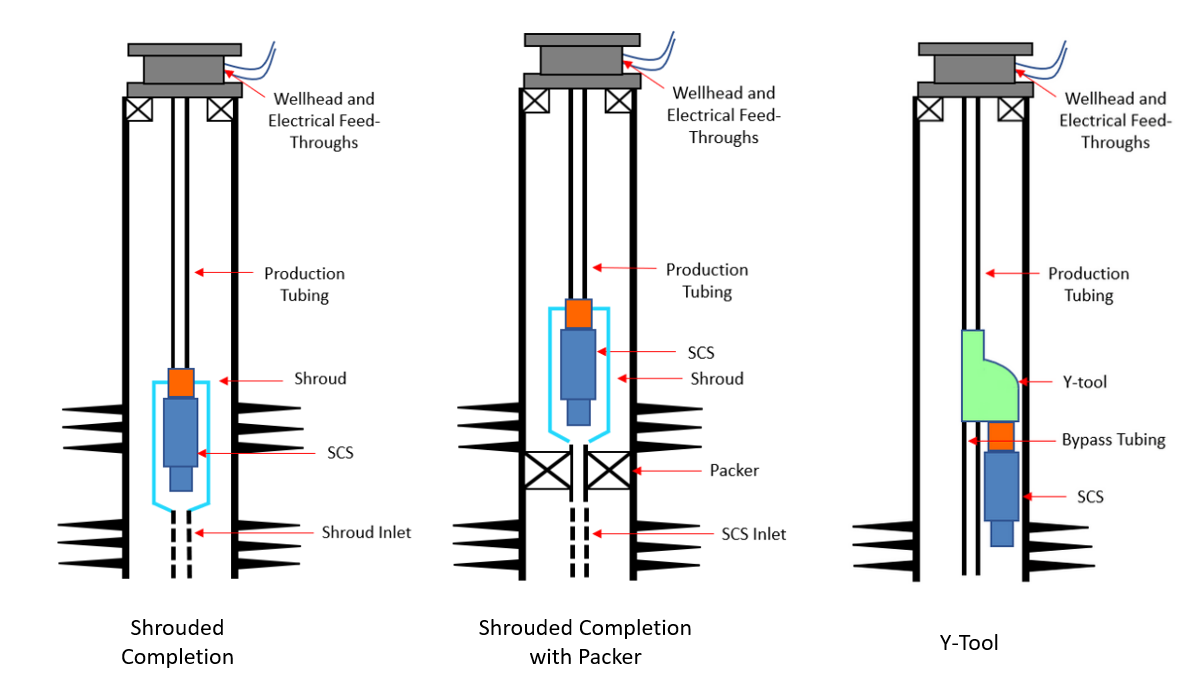

The technologies used to increase the efficiency of your completion may include:

- Centralizers

- Completion Packers

- Desanders

- Packers

- Sandface Completion Technologies

- Shrouds

- Subsurface Safety Valves

- Y-Tools

- All other standard equipment

Sample Configurations

Subsurface Compressor System in the Blocks

The Subsurface Compressor System™ (SCS) is capable of utilizing all industry standard equipment, such as those used for Electric Submersible Pumps (ESPs), to increase the efficiency of your downhole completion.

Subsurface Compressor System in the Blocks

The Subsurface Compressor System™ (SCS) is capable of utilizing all industry standard equipment, such as those used for Electric Submersible Pumps (ESPs), to increase the efficiency of your downhole completion.

Step 1

After reviewing the current wellbore, Upwing will size the motor and compressor for the application. The compressor stage will be selected to provide optimal uplift based on the current conditions of the well.

Step 2

Then, Upwing application engineers will design the downhole completion to minimize the restriction within the wellbore for the lifetime of the well.

Step 3

As needed, adjustments will be made to the downhole completion to ensure the SCS is being optimized and all components are being utilized correctly. A downhole completion will be presented for your approval, and based on your current rig schedule, an installation day will be selected.