Enabling Low-Emission Intensity Natural Gas Production

The comprehensive responsibly sourced natural gas service enabled by subsurface compression

With Upwing End2End, you get 4 services in 1.

- Analysis & Predictions

- Planning & Completions

- Deployment & Startup

- Operations & Monitoring

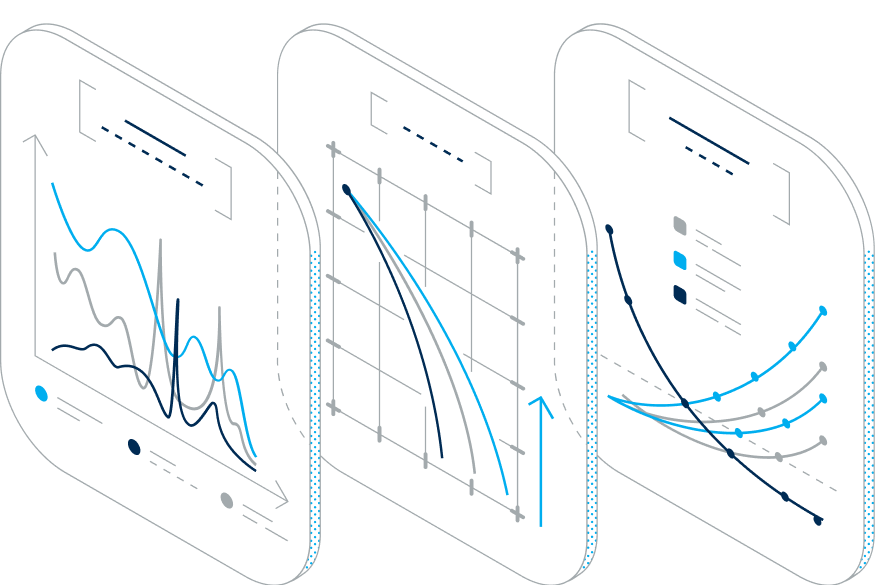

Analysis and Predictions

We conduct a full analysis on the production performance and incremental recoverability of each well with our Subsurface Compressor System (SCS).

Our analysis tools take into consideration the reservoir, well completion, topside constraints and, of course, our SCS.

Learn More

Learn More

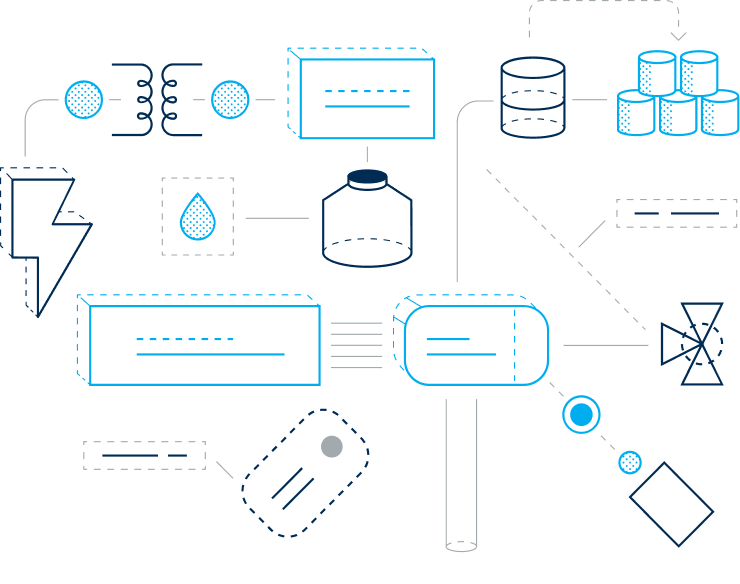

Planning and Completions

Using common industry practices and safety protocols, we plan the well site preparations, including completions, the deployment process and the startup procedures to ensure a successful SCS installation and commissioning.

All planning is reviewed and approved by your team.

Learn More

Learn More

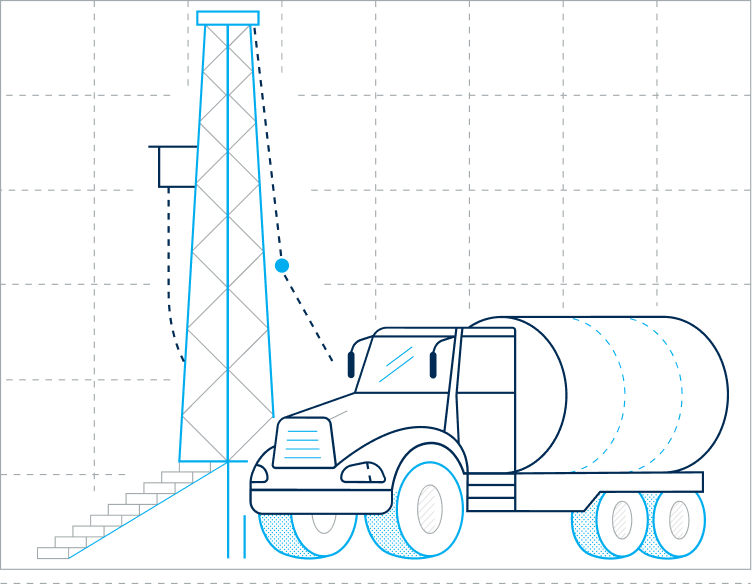

Deployment and Startup

Upwing operations personnel will oversee the deployment and startup of the SCS in the presence of your team according to the agreed upon procedures.

Learn More

Learn More

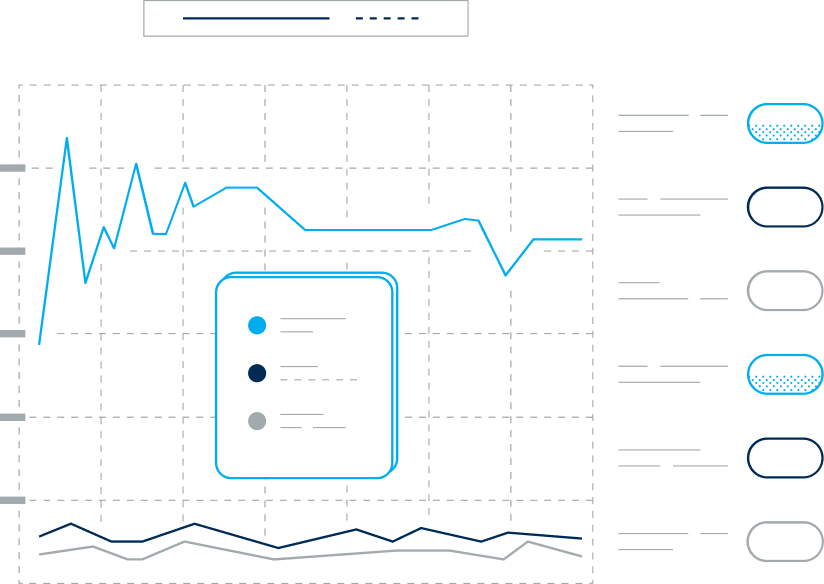

Operations and Monitoring

Control, communication and safety systems in Upwing’s topside mobile control center enable remote operation of the SCS.

Upwing personnel continually monitor and make changes to the system using real-time data to optimize production within pre-approved parameters

Learn More

Learn More